Vibration Audit

***(Pl after reading this artical click on Right Side Links for VA of specific equipment)

Vibration Audits

A. Audits can be conducted on the equipment,

-

Vibration Measurement

-

Vibration Analysis

Vibration Measurement is a simple task and gives us details of vibration readings at the machines bearings, from which we can only know the severity of vibration. It gives only overall vibration amplitude and doesn’t tell us about frequency & phase etc. It is a basic study of vibration and doesn’t require much effort. We cannot get the root causes of vibration with vibration measurements, but we can conclude whether the equipment has vibration issue and whether it needs to be rectified. If vibration measurements are done periodically, the data can be used in trend analysis.

Vibration Analysis is deep study of vibration and gives us the root causes of vibration. The Vibration Analysis also, gives us indications of future problems at very earlier stages. It also, let us knows about the foundation, base rail, distortion, soft foot, and vibration transmitted from other machines. The Vibration Analysis is carried out by two methods, FFT Analysis or Time Waveform Analysis or by both. The Phase of vibration is also an important factor in it along with frequency.

B.Vibration Audits (Vibration Analysis):

The charges for these services will be per day basis.

This includes collection of Data at site by ASNT Level I certified experts, Instrument Charges, Preliminary Report by the expert at site and Root Cause analysis by ASNT Level II certified executive, final report submission with remedial suggestions for corrective actions.

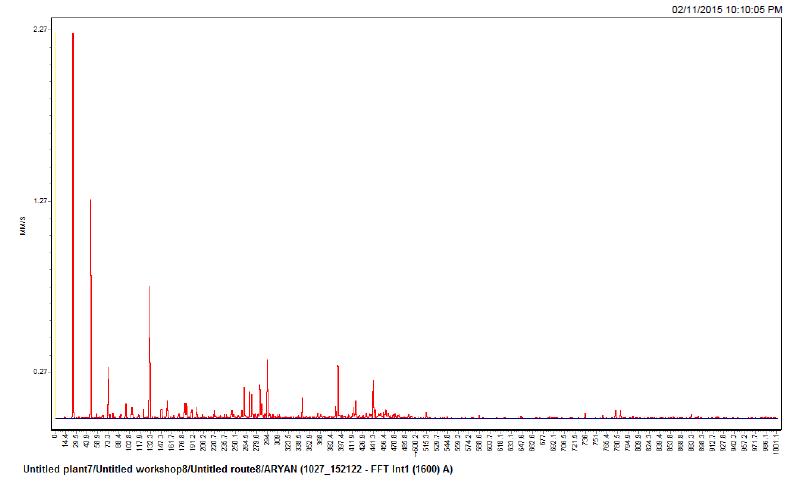

a.The Data includes FFT Spectrum, Time Waveform, and Phase of Vibration. It is specialty of our company that, we check every factor and analyze every part to reach the root cause of vibration. Different data collected from same equipment with different ranges of F max. The resolution & averages are set as per requirements.

The Analyst, studies the FFT spectrum for different vibration frequencies to find the ultimate cause of vibration at that frequencies, Compare Radial – Axial readings as well as Vertical-Horizontal readings, check whether the vibration is directional or not, confirms that the amplitudes of vibrations are within limit or not, Checks for side bands, floor rise, etc. and finally conclude on the root cause/ causes of vibration and its severity.

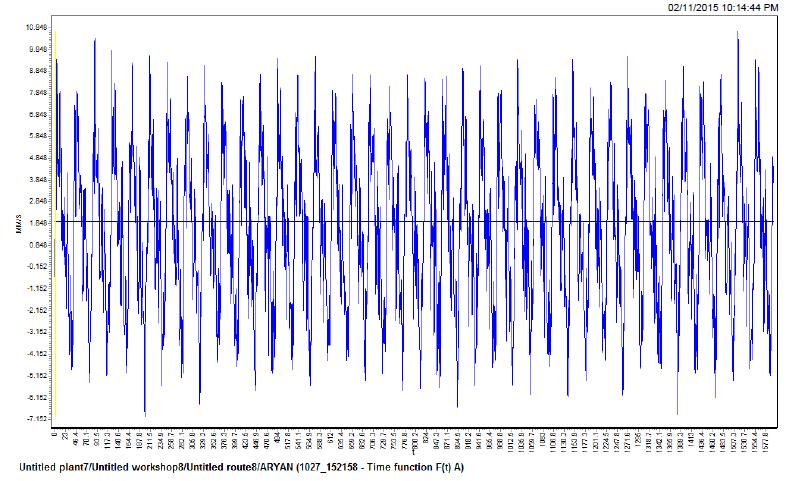

The Time Waveform gives lots of inputs to the analyst. The shape of waveform, number of waveform per time period, the exact peak to peak amplitude of waveform, the type of waveform and many such. The frequencies those might be missed in FFT spectrum might be seen in Time Waveform.

The Phase of vibration is very important aspect of vibration. The analyst finds, whether both the bearings of the object under inspection are in phase or out of phase, the vibration is directional or not, whether the vibration is transmitted from other neighboring machine to the object under inspection etc. with the help of phase measurement.

b.The expert also carry ‘Probing Studies’ to find out the quality of machine foundation, base rail distortion, loose fastening, soft foot, piping strain, etc.

c.Whenever, the vibration seems like ‘Resonance’ the experts carry ‘Bump test’ at site to confirm the resonating frequency of the object.

It is normal practice of our company to inspect the machine thoroughly for vibration, unlike others.

If the machine/ equipment are under ‘Condition Monitoring’ than the frequency of inspection is always depend on severity of vibration in that particular machine. Also, the trend of vibration is plotted and monitored closely, in order to consider the machine for corrective action well before it goes under breakdown.

Any of the above methods can be used for vibration management program in the below listed machines.